The fatigue stress concentration factor is defined as the ratio of fatigue strength of a smooth member to the fatigue strength of a notched (threaded) member [1].

It is common to model threaded members (fasteners, joints etc) as smooth cylinders within a structural analysis. The maximum stress that one may observe on the shaft of a smooth bolt would not take into account the stress concentration at the threads. Therefore, This stress cannot be used to accurately predict the fatigue life of the bolt. This is where the fatigue stress concentration factor comes in.

For cut threads, a typical value for the fatigue stress concentration factor is 4.0 [2]. This means that one may calculate the fatigue life of the member using the stress results from the FEA and then divide it by 4 to get a better prediction of the true fatigue strength.

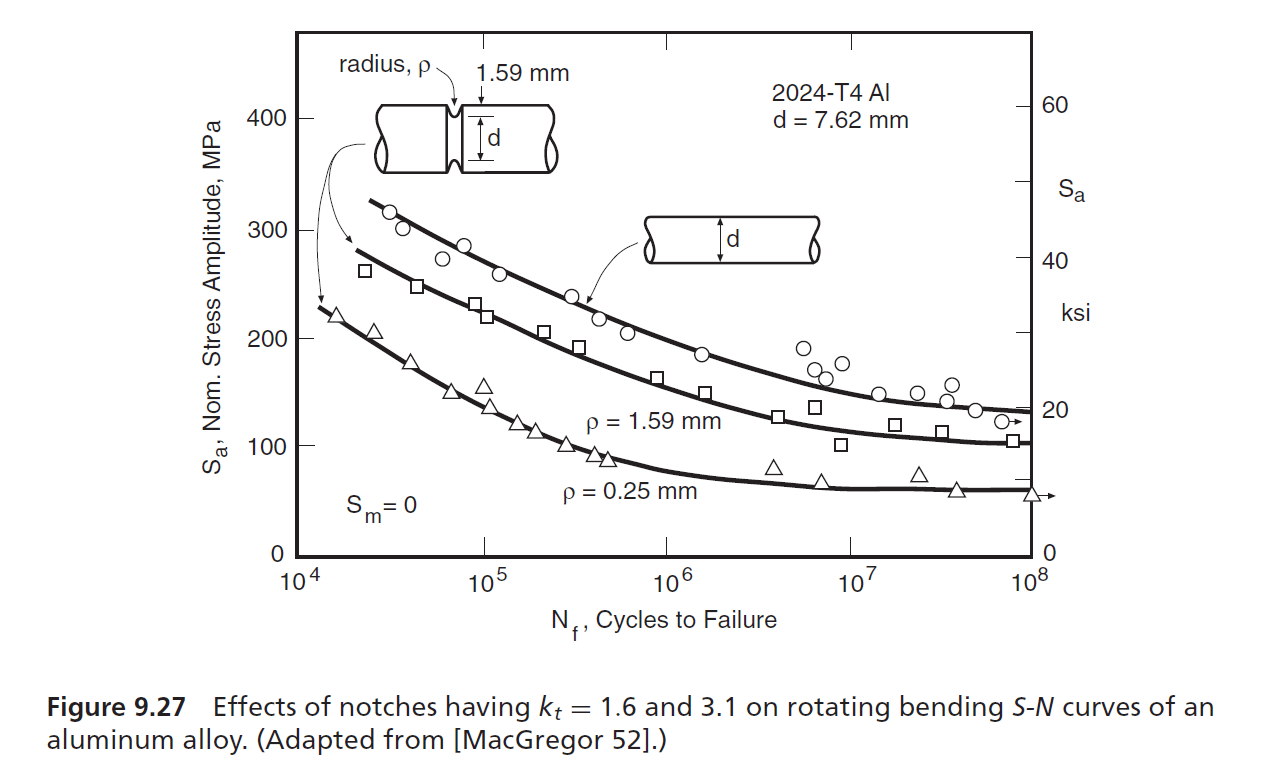

The image below [3] compares the SN curves for a smooth and notched member with 1.6 and 3.1 stress concentration factors.

References:

[1] James Hobbs, Aspects of the Stress and Fatigue Performance of Threaded Connectors, University of Sheffield, December 1998

[2] D. Arola, C.L. Williams, Estimating the Fatigue Stress Concentration Factor of Machine Surfaces, International Journal of Fatigue 24(2002) 923-930

[3] Livro Dowling, Mechanical Behavior of Materials, 4th ed. Page 444