Work hardening or strain hardening is a process through which the yield strength and hardness of a metal are increased by plastic deformation.

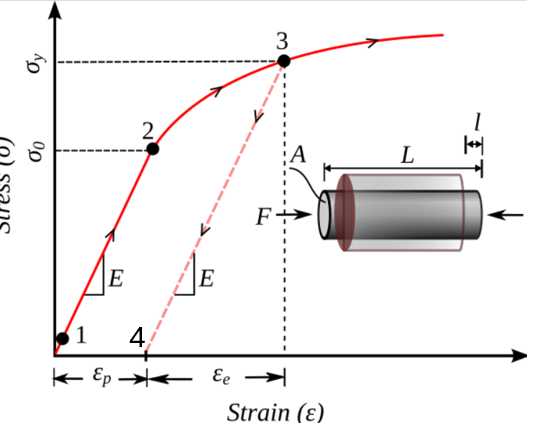

Consider the hypothetical stress strain curve shown below for a metallic specimen:

- The initial yield strength of the metal is Sigma_y.

- Suppose the specimen is loaded such that it follows line 1-2 . Line 1-2 represents the proportional or elastic limit of this specimen. If the load is released before point B is reached the specimen will return to its initial relaxed state at point A.

- The load continues to increase until point 3 on the curve is reached. The stress at this point is Sigma_y

- At this point the load is released and the specimen is allowed to relax. This is represented by the line 3-4 on the plot.

- The slope of line 3-4 is the Young’s Modulus (E), and is the same as that of line 1-2.

- The strain at point 4 is the residual strain or the plastic strain.

- If the specimen is now reloaded, it will follow the line 4-3. Note that Line 4-3 is longer than Line 1-2. The elastic limit of the specimen has increased. The yield strength of the specimen has also increased form Sigma_0 to Sigma_y.

- This increase in yield strength represents work hardening.

- Depending on the practical application, work hardening may be desirable, undesirable or inconsequential.

- The strengthening of the metal comes at the expense of reduction in ductility.