In this article we will compare Solid, Shell and Solid-Shell elements. Solid shell element technology is a recent feature included in ANSYS (SOLSH190).

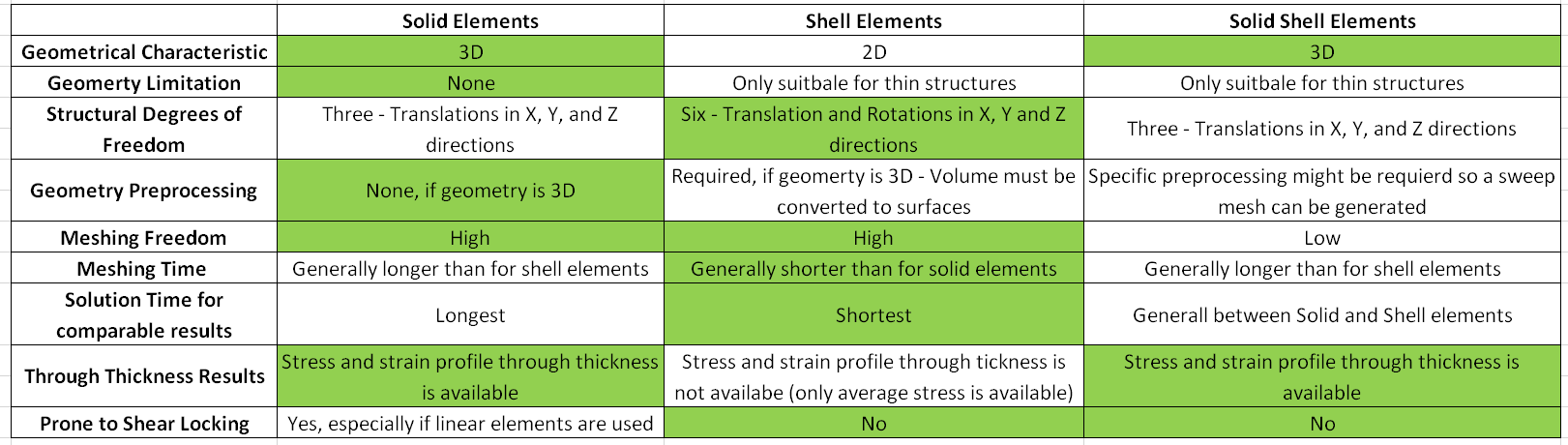

The three element types differ and are similar in various ways. It is best to compare and contrast them in a tabular form as shown below. Green highlights indicate desirable features.

Geometrical Characteristic: Solid elements are 3D. They usually consist of 4,8,10 or 20 nodes per element. Each solid element occupies volume within the model space. The same is true for solid shell elements (SOLSH190) which consist of 8 nodes. Shell elements are 2D and may consist of 2,3,4,6 or 8 nodes. Shell elements occupy surfaces within the model space.

Geometry Limitation: By geometry we imply the physical geometry of the component that we are trying to analyze. 3D elements are suitable for any geometry but Shell and Solid Shell elements are only designed to be used with structures whose two dimensions are much larger than the third dimension – such as thin-walled plates. There is no standard definition of “thin-walled” but a general rule of thumb is to consider a body thin-walled if the smallest dimension (wall thickness) is at least 20 times less than the largest dimension (length).

Degrees of Freedom: In finite element modelling (FEM), the degree of freedom (DOF) of a node represents the unknowns for which a mathematical solution will be developed for that node. In structural analysis, DOF can be translations or rotations. For solid and solid shell element, results are calculated for the X, Y and Z direction translations at each node within the element. Shell elements are superior in this regard. What they lack in geometry (they are 2D) they “make up” for by providing rotation information in addition to the translation at each node. Shell element nodes have 6 DOF.

Geometry Preprocessing: In the real world, all geometries are 3D. We can take a 3D CAD model and after the basic clean up (removing irrelevant features such as radii, chamfers, etc.) we can generate a 3D mesh with solid elements. For solid shell elements, some specific preprocessing might be required to comply with the requirements of the meshing algorithm. The solid shell elements are essentially a sweep mesh. The meshing algorithm generates a mesh on the face at one end and literally sweeps it along the length / width of the component. This means that the two faces (source and target face) must be identical.

Shell elements being 2D, require that the geometry also be 2D. 3D bodies will have to be converted into planes. Usually, a thin walled plate would be represented by a single plane at the mid surface of the cross section.

Meshing Freedom: One of the drawbacks of solid shell elements is that unlike solid or shell elements, you cannot define the mesh on multiple bodies with one meshing operation. This can become a significant issue if the model has dozens or hundreds of components. An individual meshing operation would have to be manually defined for each body where solid shell elements are defined. This is due to the sweep mesh requirement since each meshing operation needs its unique source and target faces. For large assemblies, the manual work can be very time consuming and is also prone to user errors.

Meshing and Solution Time: This is fairly self explanatory. Shell elements are the clear winner here. In fact, the run time is the main reason why one would prefer shell elements over the others. Depending on the model size and the hardware capabilities, the run time can be reduced many fold by utilizing shell elements without compromising the accuracy of the results. Solid Shell elements will generally take less time than solid elements but more than shell elements.

Through Thickness Results: If accurate stress and strain profiles through the wall thickness are desired, then shell elements can not be used. The thin wall assumption implies that the stress and strain are assumed to not vary significantly within the thickness (or we are not concerned about the variation).

Shear Locking: This is not an element feature but an undesirable phenomenon that we might observe when using linear 3D elements (Here is an explanation of linear and quadratic elements). Linear elements cannot capture bending. When the element deforms, the straight edges remain straight. This can make a body meshed with linear 3D elements artificially stiff during bending. This in turn can induce fictitious shear stresses and this phenomenon is called shear locking. The two ways to overcome this while still using 3D elements are: 1) Use quadratic 3D elements 2) Use more elements through the wall thickness. These two methods can be very expensive computationally, and this is where the use of Shell or Solid Shell elements can be very advantageous.

Shell elements explicitly account for bending at each node. The stiffness of the component is well represented. Solid Shell elements are specifically designed to overcome shear locking. The following is an excerpt from ANSYS documentation for SOLSH190 elements:

“SOLSH190 utilizes a suite of special kinematic formulations to avoid locking when the shell thickness becomes extremely small. However, due to its shell-like behavior, SOLSH190 fails to pass the patch test if the element is distorted in the thickness direction. SOLSH190 is fully compatible with 3-D constitutive relations. Compared to classical shell elements that are based on plane stress assumptions, SOLSH190 usually gives more accurate predictions when the shell is thick.“

CONCLUSION

If we consider raw accuracy, 3D quadratic elements are generally the most superior. This is also why they are the most computationally expensive. If the hardware is capable, and the run time is not undesirable, then there is no reason to use shell or solid shell elements. This is because shell elements and solid shell elements are based on some underlying assumptions to approximate the response of the thin-walled structure. These assumptions are not present with solid elements.

In some cases, hardware limitations force us to consider shell or solid shell elements. Shell elements may require a lot of preprocessing and geometry prep before the geometry becomes suitable for shell mesh generation. Additionally, if the model consists of both shell and solid elements, one has to carefully consider the behavior at the interface between solid and shell elements. Constraint equations may have to be defined at the interface.

Solid Shell elements can be incredibly useful and offer a sweet spot delivering the best of both worlds. A single element through the component thickness may produce results that are as accurate as shell elements, without having to resort to 2D elements. Additionally, there are no interface related issues as with models built with both solid and shell elements. However, the geometrical requirement for a sweep mesh (identical source and target surface) and the need to define an individual meshing command for each body may be a major deterrent.

At the end of the day an analyst has to produce the most useful result in the given amount of time. This is why they have to make a judgment call based on the following:

- Personal skill and experience: Shell elements specifically demand significant skill and experience and the learning curve might be too much of an ask in certain scenarios. In other situations, it may make more sense to learn the techniques required to develop a 2D or Solid Shell mesh.

- The level of result accuracy required: Is the project in its early phases and we are just getting a “feel” for the design, or are we nearing a design freeze? Are we going through design optimizations, or are we at the final design review stage? One may be able to utilize a coarse mesh with linear solid elements and call it a day depending on the project requirements. (Though it is still necessary for the analyst to know the limitations of the mesh, and its potential implications on the results).

- Amount of time available: Time is finite. Be it a personal project, something for the customer or for research purposes, there is always a timeline and a deadline involved. The time at your disposal will play a major role in deciding which element type to use.

I hope this article was useful in your professional / academic / personal endeavors. Good luck!

If you found this article useful, you may be interested in our eBook on FEA.