The mechanical properties of all materials are functions of the temperature of the material. When a designer chooses material properties to use in analytical or numerical calculations, (what is the difference? Read here) they (knowingly or unknowingly) assume a range of temperatures for which those material properties are valid.

When you input a material property in ANSYS, you have the option to specify a corresponding temperature. If you leave the temperature entry blank, ANSYS will assume that the property is true for the environment temperature (defaults to 22 degrees C) and does not vary with temperature. This assumption may or may not be true for your analysis.

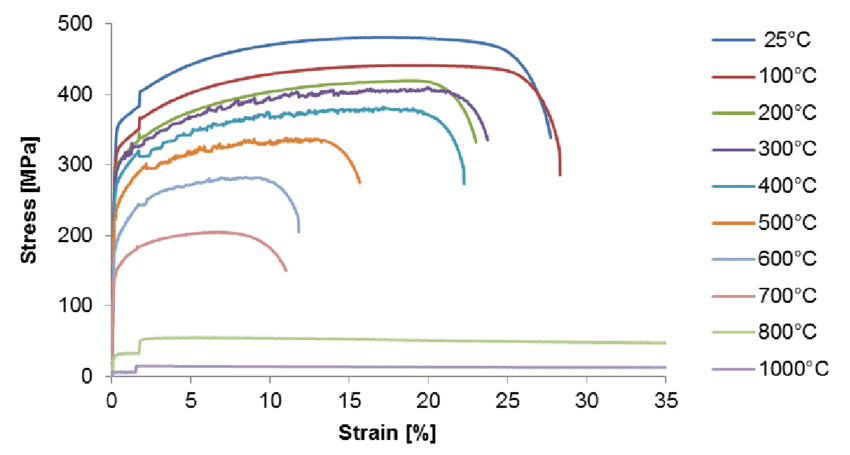

Figure 1 shows how the stress strain relationship for Steel 4509-2 at various temperatures. Steel becomes weaker as it is exposed to increasing temperatures. Based on these curves, a designer using Steel 4509-2 must consider the temperatures to which the metal will be exposed and choose the appropriate curve (or yield strength) for analysis. Below, we have listed some best practices and considerations related to the selecting temperature dependent material properties and using them with ANSYS Mechanical :

- If non-linear material properties are considered, one may input multiple stress-strain curves corresponding to various temperatures (How to input a stress-strain curve in ANSYS?).

- If linear elastic material properties are to be considered, one can input “derated” material properties. This means that modulus of elasticity and Poisson’s ratio for the material should be looked up in the relevant material properties database and for the desired temperatures. These values should be input in ANSYS mechanical.

- If the structural analysis includes temperature loads for which a stress-strain curve or elastic mechanical properties are not defined, ANSYS will perform linear interpolation using the defined curves or mechanical properties.

- For linear elastic material properties the yield strength used for calculations of the safety factors must be derated to the temperature of interest. Often times, a “thermal derating factor” is specified for the mechanical properties. For example, in the image above the yield strength at 25C is approximately 350 MPa. This drops to about 325 MPa at 100C. We will say that the thermal derating factor at 100C is (325/350 = 0.92).

- It is important to be aware that the temperature dependent stress-strain curves and derating factors are valid when the material is exposed to that temperature. However, it cannot be automatically assumed that after the material is cooled down to a lower temperature (such as room temperature) it will regain all of its lost strength. This becomes especially relevant when materials are designed to be re-used after exposure to a high temperature event (such as a fire). One must refer to relevant codes (such as the Metallic Materials Properties Development and Standardization – MMPDS) which specify the amount of strength regained by a material after cooling from a high temperature, often as a percentage of the strength at room temperature.

References

[1] Manninen, Timo & J. Saynajakangas, (2012). Mechanical Properties of Ferritic Stainless Steels at Elevated Temperature.