What is cyclic loading?

Cyclic loading is defined as the repetitive and continuous fluctuation of a load. The load may be represented via forces, stresses, or strains.

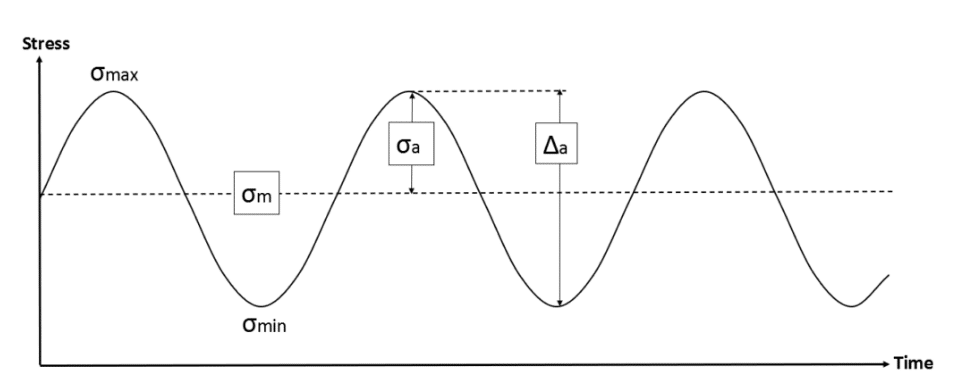

Figure 1 shows a cyclic load (stress) plot where,

Mean Stress, σm = ½(σmax + σmin)

Stress Amplitude, σa = ½(σmax – σmin)

Stress Range, Δa = σmax – σmin

What are some types of cyclic loading?

There are several types of cyclic loadings as shown in Figure 2. Several terminologies are used for these cycles and they are listed below along with their definitions.

Reversed / Fully Reserved : σm = 0, R = -1

Pulsating / Repeating : σm = σa, R = 0

Alternating / Cyclic / Fluctuating : σm > 0, R >0

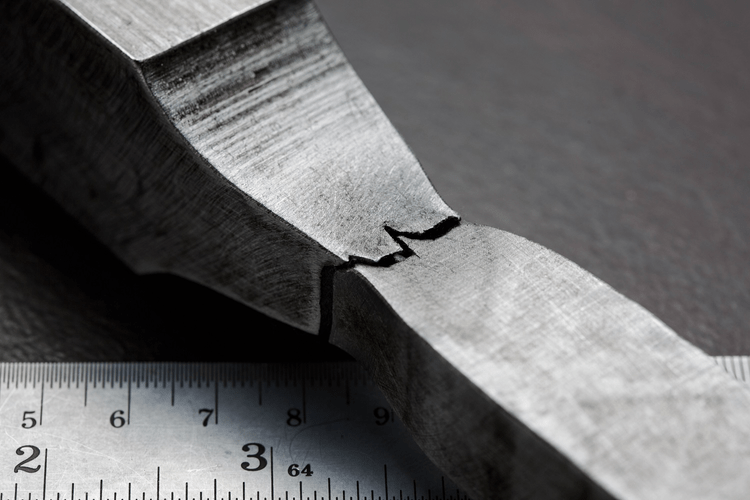

What is material fatigue?

“Fatigue is defined as a process of progressive localized plastic deformation occurring in a material subjected to cyclic stresses and strains at high stress concentration locations that may culminate in cracks or complete fracture after a sufficient number of fluctuations.” [2]

Stress intensity factor vs Stress concentration factor

The stress concentration factor is solely a function of the geometry. It is defined as the ratio of fatigue strength of a smooth member to the fatigue strength of a notched (threaded) member [3].

The stress intensity factor K, is essentially the driving force behind crack growth and represents the stress singularity a stress concentration or the tip of a crack. The magnitude of the stress intensity factor depends on the geometry, the size and location of the crack , and the magnitude and the distribution of stresses in the material.

What is fracture toughness?

“The fracture toughness KC of a material is defined as the critical stress intensity factor for immediate crack growth under given conditions.” [4]

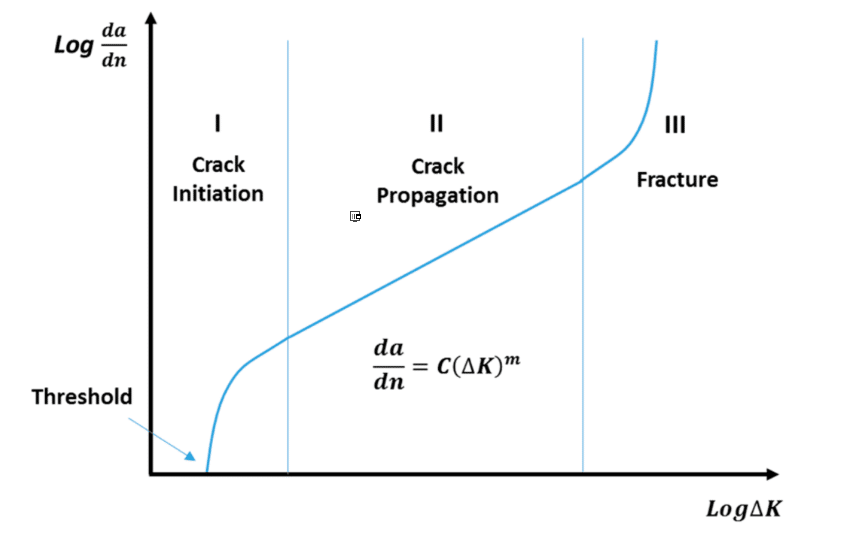

What are the stages of fatigue crack growth?

Fatigue progression is divided into three stages:

Stage I : Crack Initiation: This is the process by which cracks are formed on the surface of a material. Cracks usually initiate at free surfaces and near stress risers (regions of stress concentrations)

Stage II: Crack Propagation: Continued cyclic stress cause the crack to grow at a slow stable rate.

Stage III: Fracture: At this stage the crack grows at a fast unstable late, leading to rupture of the material.

The rate of crack growth, da/dn (crack length per cycle) can be related to the change in stress intensity factor Δk (Kmax – Kmin) as shown in Figure 3.

What is fatigue life?

“Fatigue life is defined as the number of loading (stress) cycles of a specified character that a specimen sustains before failure of a specified nature occurs.” [6]

Strain life vs Stress life approach

Strain and Stress life approaches refer to how the material response is measured or characterized for fatigue based failure. In Stress-life approach the stress amplitude is related to the number of cycles to failure. In Strain-life approach the total strain range is used instead of the stress amplitude.

Strain life approach for calculating fatigue life is useful for LCF. Stress life methods are most useful for HCF.

High Cycle Fatigue (HCF) vs Low Cycle Fatigue (LCF)

The stress-life (S-N) method relates stress amplitude to failure cycles, ideal for high-cycle fatigue (HCF) where deformation is elastic. It’s simple but inaccurate when plastic strains become significant.

The strain-life method measures total strain range (elastic + plastic) and excels in low-cycle fatigue (LCF) analysis. It captures plastic deformation effects through material coefficients, making it essential for components experiencing high strains.

The transition between methods typically occurs around 10,000 cycles. Strain-life requires more material data but provides better accuracy for LCF, while stress-life offers simplicity for HCF applications. The choice depends on expected deformation, available data, and required precision.

| Low Cycle Fatigue | High Cycle Fatigue | |

| Cycles to Failure | < 10,000 | > 10,000 |

| Stress Range | Relatively Large | Relatively Small |

| Strains developed | Plastic | Elastic |

| Procedure for fatigue life Calculation | Strain Life | Stress Life |

What is a fatigue curve?

A fatigue curve plots stress value vs fatigue life (S-N) or strain values vs fatigue life (ε-N)

What is Endurance Limit?

The endurance limit (or fatigue limit) is the maximum stress amplitude below which a material can endure infinite cycles without failure. This behavior is typical of ferrous alloys (e.g., steels).

For non-ferrous metals (e.g., aluminum, copper, nickel alloys), no true endurance limit exists. Instead, engineers use fatigue strength—the stress level at a specified life (e.g., 10⁷ or 10⁸ cycles), often plotted on S-N curves as a sloping line.

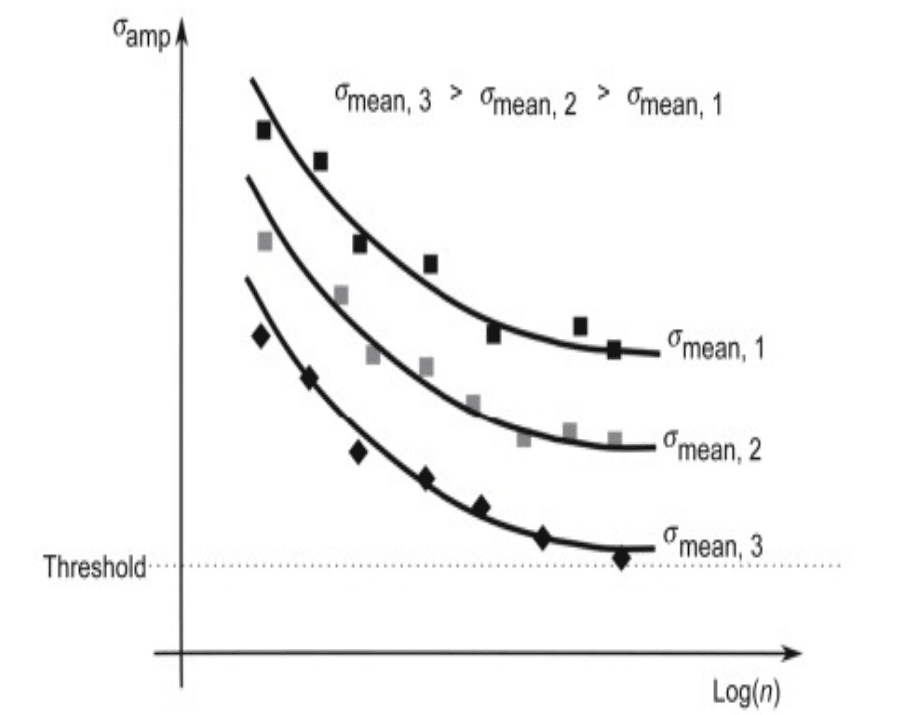

What is the mean stress correction?

Mean stress correction is a procedure where a stress cycle is converted to an equivalent cycle with zero mean stress. This is relevant because the mean stress has an impact on fatigue life even if the stress amplitude is unchanged. This is depicted in figure 5 below.

References

[1] Mechanical Properties of Materials, Joshua Pelleg

[2] Metal Fatigue Analysis Handbook, 2012

[3] James Hobbs, Aspects of the Stress and Fatigue Performance of Threaded Connectors, University of Sheffield, December 1998

[4] Iowa State University, Center for nondestructive testing

[5] Dan Liu and Dirk John Pons, Crack Propagation Mechanisms for Creep Fatigue: A Consolidated Explanation of Fundamental Behaviors from Initiation to Failure

[6] Qianfan Xin, Durability and Reliability in Diesel Engine Design

[7] Andrew Gryguc, Fatigue of Forged AZ80 Magnesium Alloy

[8] J. Zangenberg, P. Brøndsted, Fatigue life in textile composites used for wind energy engineering