Introduction

The solution of a finite element simulation is highly dependent on the quality of the mesh. A user should strive to achieve a balance between mesh quality, and time taken for mesh generation and solution. But what is mesh quality and how is it measured? In this article we will explain the various metrics or criteria which ANSYS meshing algorithm utilizes, to determine the quality of a mesh element.

Mesh Metrics

When it comes to mesh elements, symmetry and uniformity are of prime importance. Symmetrical elements with uniform sides are considered high quality elements.

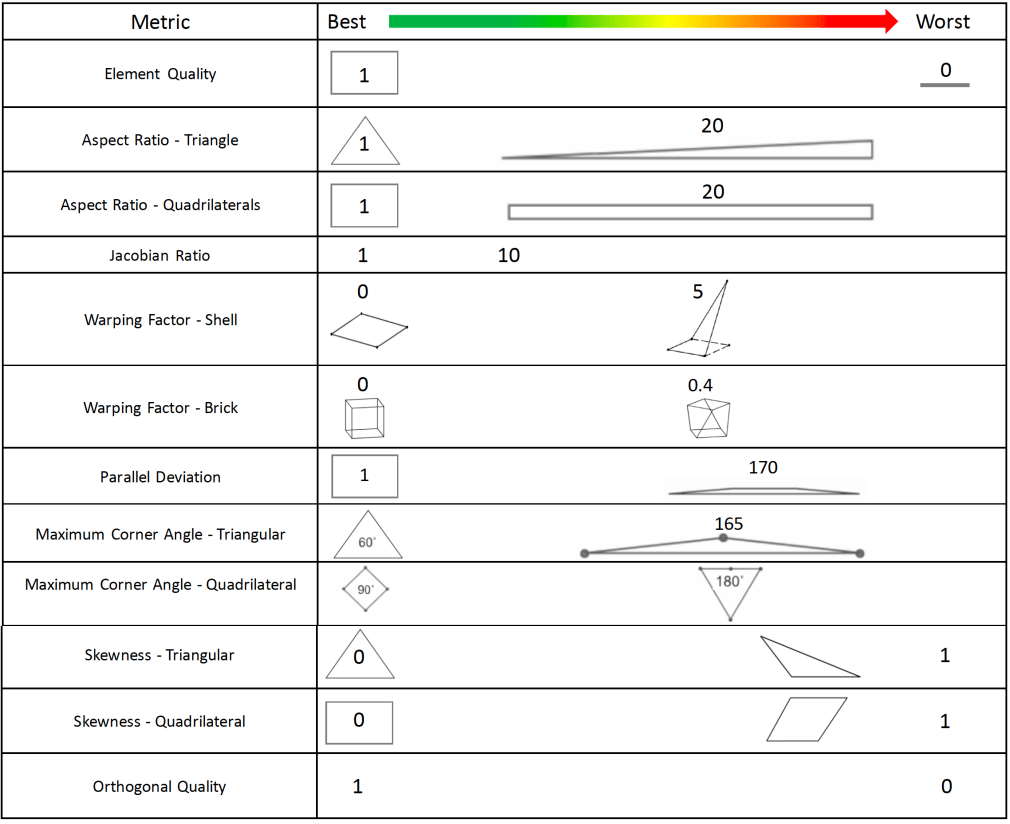

The “quality” of a mesh cell can be quantified in several ways. ANSYS performs several geometrical checks on mesh elements in order to determine their quality. These checks, or metrics are:

- Element Quality

- Aspect Ratio Calculation for Triangles

- Aspect Ratio Calculation for Quadrilaterals

- Jacobian Ratio

- Warping Factor

- Parallel Deviation

- Maximum Corner Angle

- Skewness

- Orthogonal Quality

Each of these metrics represent particular geometric aspects of the elements and can be measured by numbers. ANSYS help provides details on these metrics. Here we will provide a brief summary of each metric (taken from ANSYS documentation [1]) in a way that it can be of benefit to the average FEA analyst, without delving into the mathematical details.

Element Quality

The Element Quality is based on the ratio of the volume to the sum of the square of the edge lengths for 2D quad/tri elements, or the square root of the cube of the sum of the square of the edge lengths for 3D elements.

The Element Quality is a composite quality metric that ranges between 0 and 1.

A value of 1 indicates a perfect cube or square while a value of 0 indicates that the element has a zero or negative volume.

The following are Ansys recommendations for Element Quality:

Aspect Ratio Calculation for Triangles

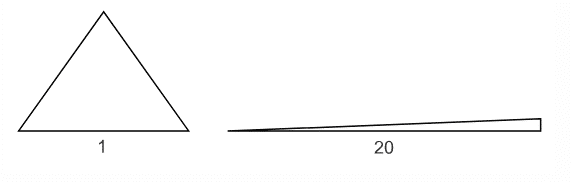

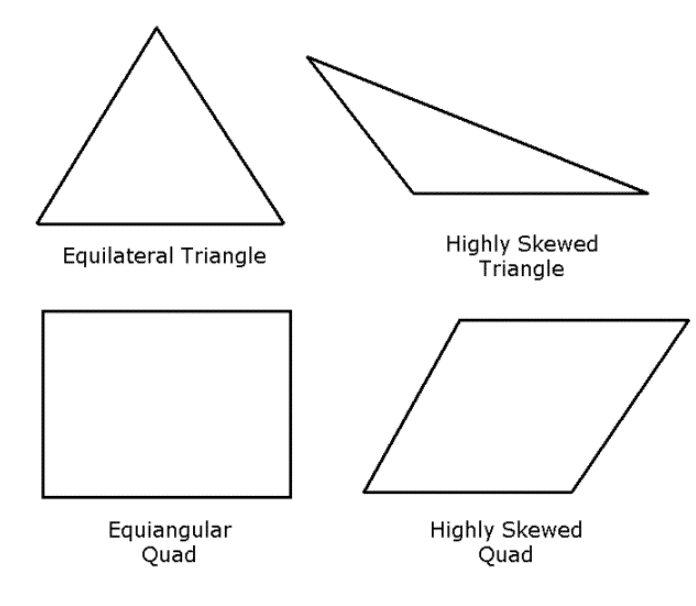

The aspect ratio of a triangle provides a comparison of the “height” and “width” of a triangle.

It varies from 1 to infinite. A value of 1.0 indicate an equilateral triangle.

The image below shows triangles with aspect ratios of 1 and 20.

Aspect Ratio Calculation for Quadrilaterals

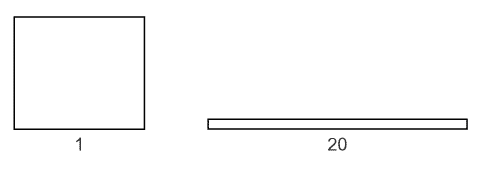

The aspect ratio of quadrilaterals provides a comparison of a long side to a short side of the quadrilateral.

It varies from 1 to infinite. A value of 1.0 indicates a square.

The image below shows quadrilaterals with aspect ratios of 1 and 20.

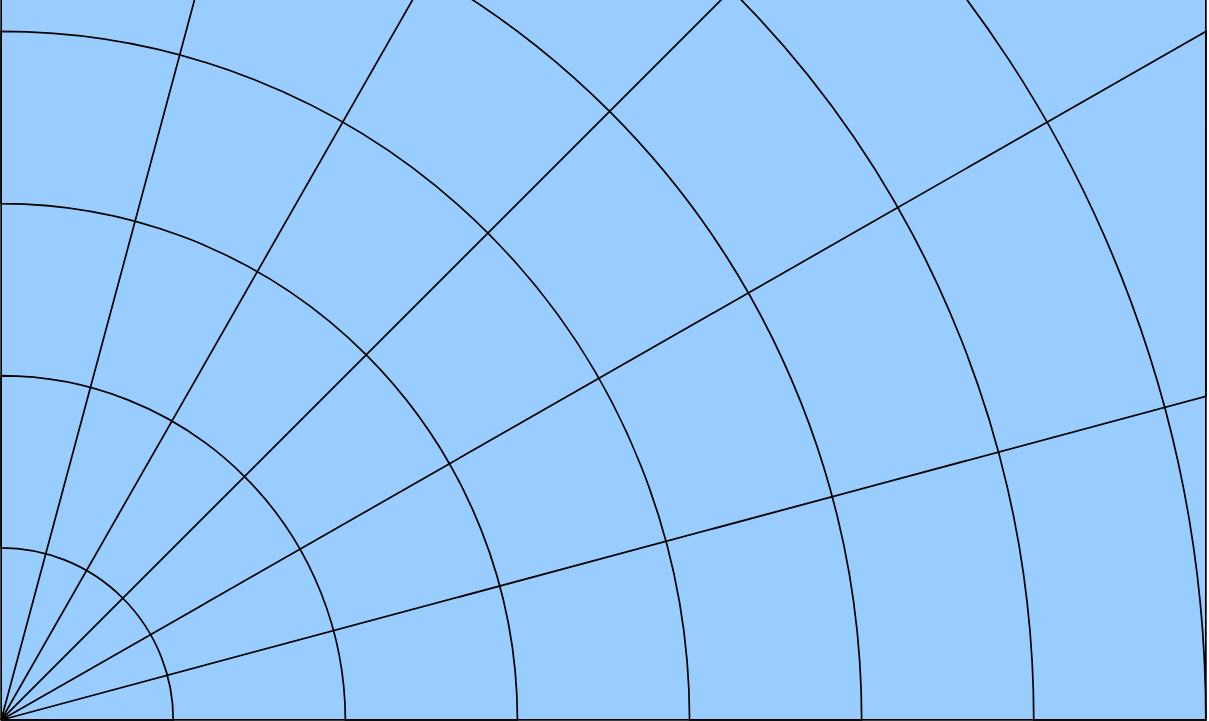

Jacobian Ratio

The Jacobian ratio is a measurement of the shape of a given element compared to that of an ideal element. The ideal shape of an element depends on element type. The ideal Jacobian ratio is 1.0 and a good quality mesh has a Jacobian ratio between 1 and 10 for the majority of its elements (90% and above) [2].

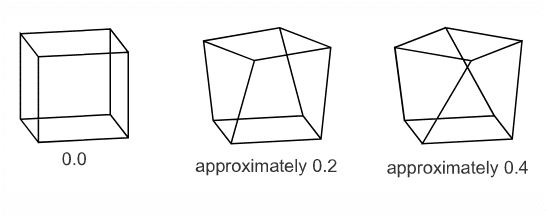

Warping Factor

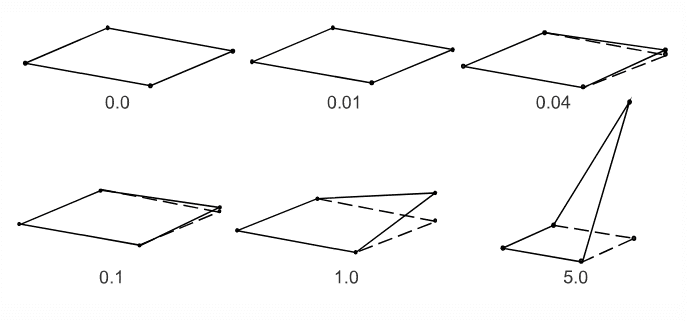

Warping factor is computed and tested for some quadrilateral shell elements, and the quadrilateral faces of bricks, wedges, and pyramids.

The ideal warping factor is 0. Warping is a measure of twisting and distortion and is best understood by looking at quadrilaterals with varying warping factors.

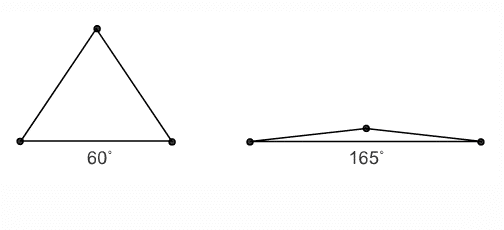

Parallel Deviation

Parallel deviation is a measure of how much two parallel sides of a shape deviate. The ideal parallel deviation is 0 for a square.

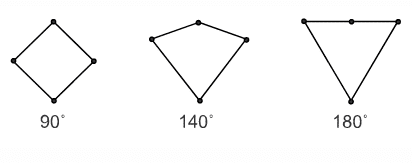

Maximum Corner Angle

This is the maximum angle between adjacent edges of an element. For a triangle the best maximum angle is 60 degrees. For a quadrilateral it is 90 degrees.

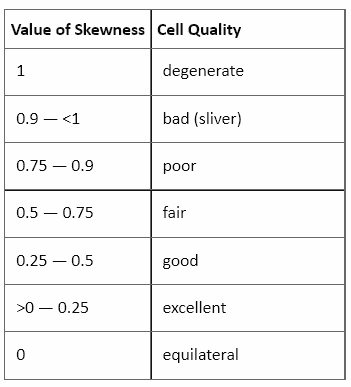

Skewness

Skewness is one of the primary quality measures for a mesh. Skewness determines how close to ideal (equilateral or equiangular) a face or cell is.

Orthogonal Quality

The range for orthogonal quality is 0-1, where a value of 0 is worst and a value of 1 is best.

Summary

It is useful to summarize the information that we have seen so far in a tabular form. We have developed the table shown below for this purpose. You may use this table when verifying the quality of your mesh.

References

[1] ANSYS help

[2] SolidWorks help