How to Choose the Right Mesh Size in Ansys Mechanical

Getting your mesh right in Ansys Mechanical is like tuning a race car—too coarse and you’ll miss critical details, too fine and you’re burning time on overkill. This guide reveals professional strategies to balance accuracy and efficiency.

Why Mesh Strategy Matters

Every FEA engineer knows mesh sizing directly impacts results, but assembly simulations add complexity. Different components have competing requirements, and contact interfaces demand special attention. The secret? A tiered approach that applies the right resolution where it matters most.

Key Mesh Planning Questions:

Before applying any mesh settings, it’s essential to step back and define the purpose of your analysis. Mesh refinement should be driven by the physics of the problem, the geometry, as well as the time and computational resources available. Asking the right questions early on helps ensure your mesh supports meaningful, reliable results without unnecessary computational cost.

- What’s the primary analysis objective? ( Global stiffness? Local stresses? Modal frequency?)

- Where are the critical stress regions? (Fillets, holes, contacts, welds)

- Which components drive overall behavior?

- What is the expected load path? (This helps identify where stresses will concentrate)

- Are there nonlinear effects involved? (Contact, plasticity, or large deformation? These demand finer, adaptive meshing)

- Will the results be used for certification or compliance? (Some standards require documented convergence or element size thresholds)

Step 1: Establish Your Global Baseline

Start with a sensible default size that captures the overall geometry.

Practical Formula:

Global Element Size = (1/5 to 1/10) × Smallest Significant Dimension

(e.g., wall thickness, hole diameter, or smallest load-bearing feature)

Example: For a 25 mm thick bracket:

- Coarse mesh: 5 mm (1/5)

- Fine mesh: 2.5 mm (1/10)

- Recommended start: 3–4 mm

🔧 Pro Tip: Use “Mesh Metrics” in Ansys to inspect element quality at this stage.

⚠️ Note: This is a rough starting point, not a universal rule. It may not work well in cases involving large deformations, thin features, or dominant contact behavior (e.g., thin gaskets or flexible seals may require much finer resolution). Conversely, using a very small feature to define global mesh size can lead to excessive refinement, dramatically increasing meshing time and solve time without improving results in less critical regions.

Step 2: Smart Local Refinement

Not all areas deserve equal attention. Prioritize regions that drive results:

1. Stress Concentration Zones

Focus on geometric features where stress gradients are expected to be high:

- Fillets and sharp corners

- Holes and cutouts

- Weld seams and notches

- Material transitions or thickness changes

Use appropriate local mesh controls (e.g., Face Sizing, Body Sizing, or Refinement Zones) to ensure smooth and accurate stress capture in these areas. For smoother transitions between coarse and fine regions, consider using tools like Sphere of Influence or Proximity-based sizing.

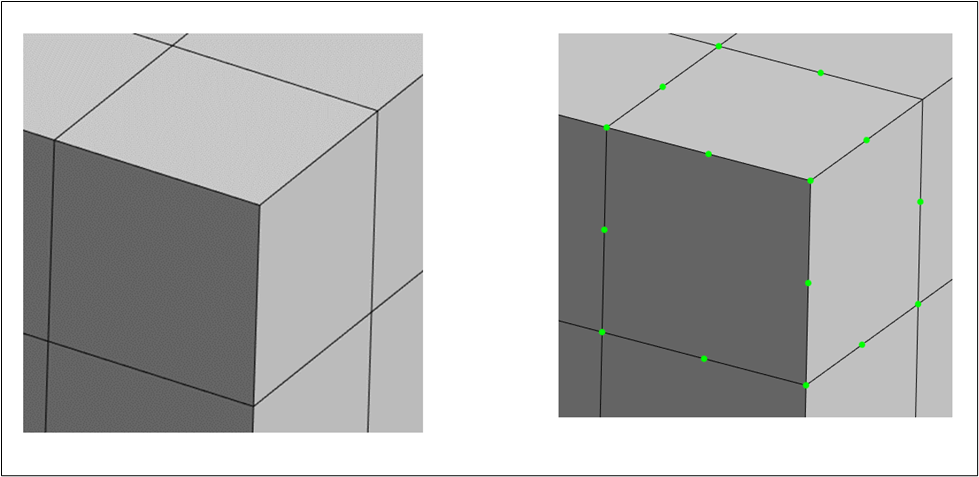

2. Contact Regions

Proper meshing near contact interfaces is essential for convergence and stress accuracy.

- Bonded contacts: A 2:1 element size ratio (one side having elements up to twice the size of the other) is usually acceptable. Since there’s no sliding or separation, a perfect node-to-node match isn’t necessary.

- Frictional contacts: Aim for a 1:1 element size match across the interface. Mismatched mesh densities can cause inaccurate pressure distribution and convergence issues in frictional or sliding scenarios.

Use Contact Sizing to enforce mesh consistency across contact faces and avoid artificial stress concentrations.

🔍 Contact Interface Quick Reference

| Contact Type | Mesh Strategy | Special Considerations |

|---|---|---|

| Bonded | 2:1 element size ratio | Node mismatch is acceptable; watch for artificial stress spikes |

| Frictional | 1:1 element size match | Required for accurate pressure and contact behavior |

| No Separation | Moderate refinement | Tune pinball region and contact stiffness carefully |

3. Thin Structures

Thin parts (e.g., plates, brackets, shells) require special care in mesh planning to capture bending and through-thickness stress accurately.

- Aim for 3 elements through the thickness as a general rule. This usually provides sufficient accuracy in bending and shear behavior.

- What matters is not just element count, but nodal resolution. Higher-order elements (like 20-node hexahedral or 10-node tetrahedral) require fewer layers than linear elements to achieve comparable accuracy (Read: Linear vs Quadratic Mesh Elements)

- For very thin parts, maintaining 3 solid layers may require extremely small elements—leading to high element counts – As an alternative, consider using solid-shell elements (available in Ansys) for thin bodies with high in-plane dimensions. These offer excellent bending accuracy without requiring multiple solid layers (Read : Solid vs Shell vs Solid-Shell Elements)

Step 3: Validation & Optimization

🔁 Convergence Study Protocol:

A convergence study (also called mesh independence or mesh sensitivity study) is essential for verifying the reliability of your results—but in large assemblies, refining the entire mesh globally isn’t always practical. A blended approach using both global and targeted local refinement is often more efficient.

- Start with a baseline analysis using a reasonable global mesh and initial local refinement in critical areas (See Step 1).

- Identify key output metrics (e.g., peak stress, displacement at a load path, contact pressure).

- Refine strategically based on your analysis goals:

- Global refinement is ideal when you’re focused on system-level behavior—such as global stiffness, overall deflection, or modal frequencies. Coarsely refine the entire model (e.g., reduce global element size by 20–30%) and observe how global response changes.

- Local refinement is more appropriate when detailed accuracy is needed in specific regions—such as stress concentrations, contact zones, or fatigue hotspots. Focus mesh density only where gradients are high or results are sensitive.

- Compare results between refinements. Look for relative changes in the key outputs you’re tracking.

- Repeat refinement (globally or locally) until result changes fall below an acceptable threshold—typically <5% for design verification, and <2% for high-accuracy studies.

⚠️ Tip: Use tools like mesh convergence plots, submodeling, and local refinement controls to streamline convergence studies—especially in large assemblies where global refinement is costly.

🧠 General Efficiency Strategies

- Combine parts using Multibody:

Merge welded or tightly connected parts into a single Multibody Part to eliminate internal contacts and reduce solver complexity. - Use symmetry wherever applicable:

Model only a symmetric portion (½, ¼, etc.) and apply symmetry boundary conditions to reduce mesh size while preserving accuracy. - Apply submodeling for critical regions:

Analyze high-stress areas (e.g., bolted joints, welds) with detailed sub-models driven by boundary conditions from a coarse global model. - Use mesh controls sparingly:

Avoid excessive local sizing that leads to poor transitions or unnecessary element growth. Refine only where needed. - Limit fine mesh to stress gradients:

Use initial results to guide local refinement—refining the entire model “just in case” leads to wasted compute resources. - Use sweep meshing when possible:

For prismatic parts like brackets or ribs, sweep meshing produces structured elements with better accuracy and fewer distortions. - Suppress non-critical parts during setup:

Remove or simplify cosmetic and non-load-bearing features during early runs to reduce preprocessing and solve time. - Simplify fastener modeling:

Use springs, pretension sections, or beam elements for bolts unless you’re studying stress within the bolt itself (Also Read: A guide to applying pretension in Ansys Mechanical)

🔧 Advanced Techniques for Tough Cases

For more complex or high-precision simulations, standard mesh controls may not be enough. The techniques below are commonly used by advanced users to handle nonlinear behavior, tight convergence tolerances, or iterative design workflows.

We’ll explore each of these in upcoming articles, with step-by-step examples, practical applications, and expert tips to help you implement them effectively.

- Adaptive Meshing:

Let Ansys automatically refine the mesh based on error estimates or user-defined goals. Great for contact zones and nonlinear regions. - Manual Node Matching:

Where high-accuracy contact interaction is required, align nodes across interfaces to avoid interpolation errors. - Element Order Switching:

Use quadratic elements (higher-order) for stress and curvature accuracy, and linear elements for better contact behavior or when memory is limited. - Use mesh reuse and morphing:

In parametric design studies or shape optimization workflows, geometry changes between iterations are often small (e.g., adjusting a hole diameter or a fillet radius). Instead of regenerating a new mesh each time, you can reuse the original mesh or morph it to fit the new shape.

This significantly reduces preprocessing time and ensures consistent element topology across all variants—making result comparison more reliable and minimizing mesh-induced variation. In Ansys Workbench, this can be done using mesh copy, morphing functions, or shared topology in parametric models.

Final Checklist & Closing Thoughts

Before clicking Solve, make sure your model meets the following criteria:

✅ A reasonable global mesh size is applied based on geometric scale and analysis objectives

✅ Critical regions (e.g., stress risers, contact zones, thin features) are refined appropriately

✅ Contact interfaces are meshed with compatible sizing and element quality

✅ A convergence strategy—global, local, or hybrid—has been planned or executed

There’s no such thing as a universally “perfect” mesh. What matters is that your mesh is fit for purpose: accurate enough to trust your results, yet efficient enough to run within your project’s time and resource limits.

A well-designed mesh reflects engineering judgment. It balances physical fidelity with computational practicality, and it evolves as your understanding of the model improves. With careful planning and targeted refinement, you can produce reliable results—without over-meshing or wasting compute time.