Introduction

ANSYS Design Modeler and Space Claim provide the option to combine bodies into Multi-Body Parts. There are several advantages and disadvantages of doing this. In today’s article we will take a concise look at some aspects of creating Multi-Body Parts.

What is a Multi-Body Part?

As the name suggests, a Multi-Body Part (MBP) is a component which is made up of multiple bodies. ANSYS will treat each body within the part as a separate entity within the tree, but the bodies will be associated with a single part. The image below (taken from ANSYS Space Claim Help) shows a tree with 6 single body components (named “solid”) and two MBPs (named “Midsurface – Solid”). Each MBP consists of two bodies.

How do you create a Multi-Body Part?

Creating a MBP is simple. In Space Claim (SC) you can select multiple bodies, right click, go to component and select “Move to New Component“. The new component is essentially a MBP.

In Design Modeler (DM) you can select multiple bodies, right click and select “Form New Part“. The DM steps and terminology are clean and self-explanatory.

What are the advantages of creating Multi-Body Parts?

There are several advantages of creating MBPs. When you create a MBP you end up grouping components and this could be desirable for various reasons. The most important one is to create a conformal mesh between parts (more on this later) though there are some other less obvious advantages as well.

1) Tree Organization

You can group components to have a more organized and clean looking tree. This could be useful for quick reference and access to various components.

2) Component Tracking

Bodies can be grouped based on some similarities. For example, you may want to group together bodies with the same material, similar size or their functions within the assembly.

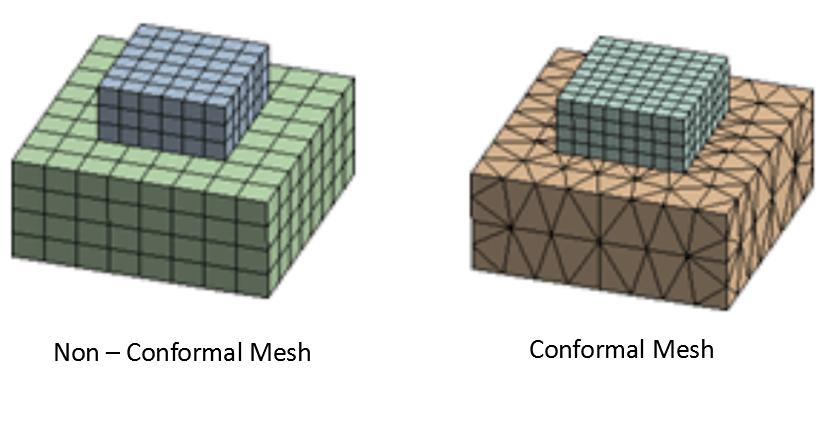

3) Creating a Conformal-Mesh

As mentioned earlier, this is the most commonly used reason for creating a MBP. A conformal mesh between two parts implies that the parts share nodes at the interface of the two parts. The mesh will be continuous across the bodies at the shared face / edge. For this to happen, all bodies within the part / component must share a face or edge and the shared topology option must be set to “share” or “imprint”. The image below shows the difference between conformal and non-conformal meshes for the two mating blocks. The mesh nodes at the base of the smaller box are shared between the two bodies for the conformal mesh. This is not true for the Non-Conformal Mesh.

Below is an excerpt from Space Claim help explaining what each of the shared topology options means:

The Shared Topology settings are:

- None (default) does nothing to geometry during transfer to ANSYS/Workbench

- Merge is intended only for Baffles used in CFD analysis:

- It merges surfaces that are fully embedded within a solid. Surface edges that lie on the solid are valid. Surfaces that intersect the solid are not valid and must be trimmed before executing Shared Topology.

- Share imprints and merges all bodies in the components and transfers the result to ANSYS as a multi-body part

- Group groups all bodies in a component into a multibody part, but does NOT merge or share faces and edges of the bodies with each other

4) Eliminate the need to define bonded contacts

This is a natural result of having a conformal mesh. A conformal mesh essentially forces the mating surfaces / edge to have the same displacements. For this reason, actual contact definitions are not required to bond the parts together. This could be especially useful and save time and effort in large assemblies with multiple bonded contacts.

What are the disadvantages of creating Multi-Body Parts?

There are some disadvantages of creating MBP as well:

1) Requires manual Pre-Processing

One has to create MBPs manually. This can take significant time and effort for large assemblies.

2) Generating a mesh can be challenging and time consuming

In my opinion, this is the largest deterrent to creating MBPs. By definition, the mesh on a MBP has an additional constraint when compared to Single Body Parts. In addition to the mesh settings, there is a limitation on the meshes to share nodes at the interface of the MBP, which means that many of the initial meshing attempts with user defined mesh setting would fail. This can be quite frustrating. Also, the sequence in which the parts are meshed affects the overall “meshability” of the MBPs. Sometimes, you may have to generate the mesh on the bodies with the finest mesh first and then sequentially move up to the parts with the coarser meshes in order to avoid meshing failures. ANSYS would give you a warning that the mesh sequence is not being recorded. If you want the mesh to be generated with a single command and be repeatable, you may have to record your meshing sequence, so it can be followed automatically by the mesher.

3) You lose the ability to access information which would be available with a contact definition

This is fairly obvious but it is still something worth keeping in mind. Defining manual contacts do come with additional abilities such as being able to post-process contact pressure, penetration etc. You also have quicker access to getting force and moment information through the force probes.

4) Shared Topology options and results can be buggy and inconsistent

This is not something which would happen in an ideal scenario, but it does happen often enough to make it a genuine concern, especially for larger assemblies. I have had situations where MBPs were correctly defined with the appropriate shared topology settings in DM, but this would not translate to getting a conformal mesh in Mechanical. There is no logical explanation for this, other than the fact that there is some of loss of information somewhere along the process, and instead of catching and reporting it, ANSYS just ignores it and generates a non-conformal mesh across the mating bodies. For relatively small models, one could manually verify the mesh continuity along the bodies in a MBP, but this may not be feasible or desirable for larger assemblies. It is what it is and one has to be careful.

Summary and Conclusion

Generating Multi Body Parts can be a useful modeling strategy in some scenarios. The primary advantage of this is achieving a conformal mesh across bodies and eliminating the need of defining bonded contact definitions. However, there can be pitfalls in this process, especially the increased difficulty of generating a successful mesh. Every model is different as is every analyst. The decision to prefer MBP over SBP depends on one’s ability to understand the needs of the project, their own abilities, and the advantages and disadvantages associated with utilizing MBPs.