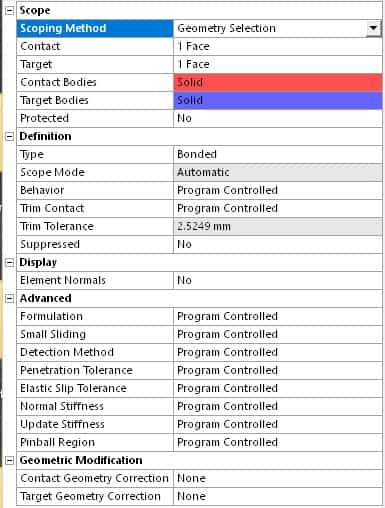

ANSYS Mechanical comes with an extensive set of options for contact definitions between components. In this article we will take a look at each one of the contact settings and explain what it does, and how best to utilize some of them.

Scoping

- Scoping Method

The two items here are “geometry” and “Named Selection”. If you pick geometry, then you will need to specify the face / faces for the contact and target regions. Alternatively, if you have the relevant face(s) defined via Named Selections, then you can use the Named Selection (NS) options. The main benefit of using NS is the ease of re-selecting the surfaces (especially if you have a lot of them).

2. Contact and Target

The contact and target form a contact pair. In simple terms, when two separate bodies touch each other, contact and target represent the two bodies. This means that the nodes on the contact surfaces will be prevented from penetrating into the volume of the target surface. Compressive normal forces and tangential shear forces can be transmitted across the contact pair. We will get back to contact – target pairs when we discuss “Behavior”. Here is a video by ANSYS explaining how to designate contact / target side properly and this article summarizes the video for easy reference.

3. Protected

This refers to protecting a topology (geometric features) prior to meshing. ANSYS help documents this as follows”

“Protected topology will result in having a better association between the mesh topology (nodes, faces, elements) and the geometry features (topology).That is,

- A geometry vertex should have a node associated to it.

- A geometry edge should have mesh nodes/edges associated to it.

- A geometry faces should have mesh nodes/faces/elements associated to it.

- A geometry body should have mesh nodes/elements associated to it.

Since boundary conditions are ultimately applied to the mesh, it is important to have proper associations to get proper loading. Thus, if protected topologies are ignored, an error or warning message may be issued by the mesher.”

Check out FEA Tips eBook – All Models are Wrong

Definition

- Type

Five types of contact definitions are available

- Bonded: The two bodies are tied together. It is as if the two components are glued. This setting is widely used whenever two bodies are expected to move together. For example, a plate welded onto a beam.

- No Separation: Frictionless sliding is allowed but the bodies do not separate. For example, wipers moving on a car windshield.

- Frictionless: Separation and frictionless sliding are allowed.

- Rough: Separation is allowed but sliding cannot occur.

- Frictional: Separation and frictional sliding are allowed.

| Type | Separation | Sliding |

| Bonded | No | No |

| Rough | Yes | No |

| No Separation | No | Yes – frictionless |

| Frictional | Yes | Yes – frictional |

| Frictionless | Yes | Yes – frictionless |

2. Scope Method

This is greyed out since it is a read-only property. It shows how the contact was defined – manually by the user, or automatically by the software (using automatic contact generation).

3. Behavior

- Asymmetric: The nodes on the contact surface are prevented from penetrating into the target surface. This is typically the most efficient method to model face-to-face contact for solid bodies.

- Symmetric: The nodes on the contact and target surface are prevented from interpenetrating . This is computationally more expensive than asymmetric contact. Also, this makes contact force processing tricky since the average of the load reaction on the contact and target sides gives the net load reaction on the contact interface.

- Auto Asymmetric: The solver automatically created an asymmetric contact pair.

- Program Controlled: The solver defaults to a setting based on the body types:

| Body 1 | Body 2 | Program Controlled Behavior | Condition |

| Flexible | Flexible | Auto Asymmetric | |

| Flexible | Rigid | Asymmetric | |

| Flexible | Flexible | Symmetric | Scoped to Non-Linear Adaptive Region |

| Rigid | Rigid | N/A – Must be defined manually |

4. Trim Contact

This feature can reduce the solution time by reducing the number of contact elements to be considered by the solver. If set to ‘on’ the solver determines the proximity between the source and target elements and the elements that are ‘far’ (based on a tolerance setting) are ignored from contact calculations. This is also the default program controlled setting.

5. Trim Tolerance

This is the tolerance setting mentioned in the previous point. When checking for node proximity, the solver creates bounding boxes for the elements. Only the elements are considered whose bounding boxes overlap (contact overlaps with target). You can manually set this value to modify the size of the bounding box.

6. Contact and Target APDL Name

These properties are optional and enable you to specify an APDL parameter name for the contact and the target element types. Using these names, you can easily identify the contact and target element type and their corresponding real constant set that you can reference and use in an APDL command object.

7. Suppressed

Defines weather the contact is suppressed for physics or not

Display

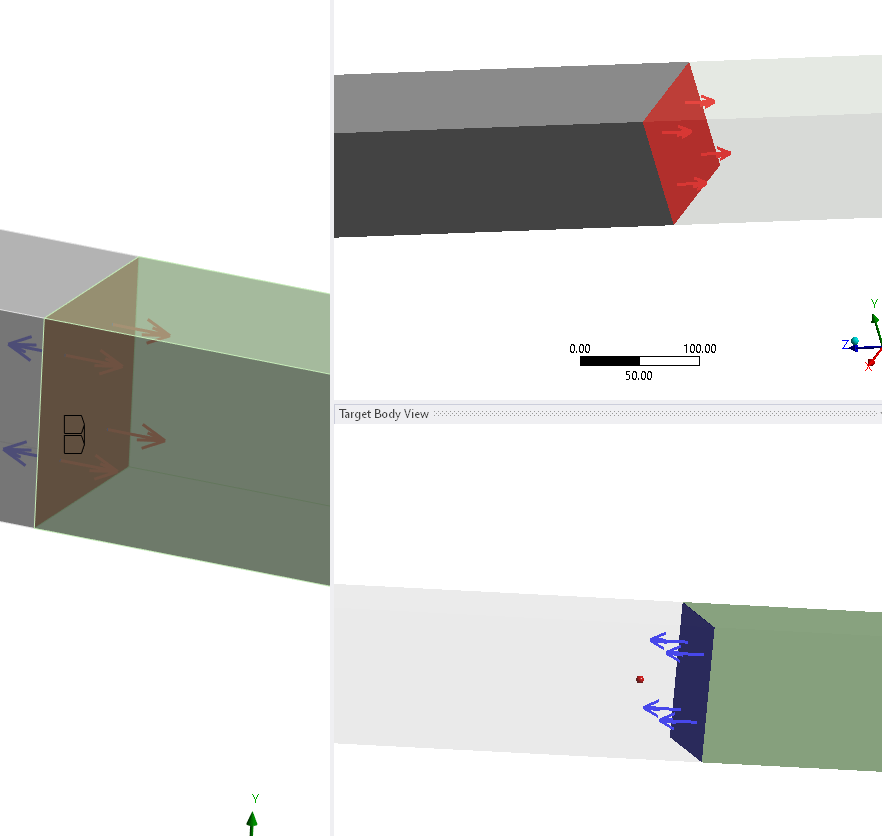

- Element Normals: An element normal is a vector normal to the face of an element. If selected to yes, the normal vectors for the contact and target face will be displayed as shown below:

Advanced

- Contact Formulation Settings

This is covered in a separate article – contact formulation settings.

2. Small Sliding

This setting activate an assumption that the contact sliding is limited to less than 20% of the contact length during the simulation. If turned on, this can makes solutions more efficient. The default setting for this is ‘on’ in most cases when Large deflection is set to “off” (Non-Linear Geometry set to off). If this setting is active for a contact and the contact slides more than the limit, a warning message will appear, making the user aware of this.

Adaptive Small Sliding was included in Ansys version 2022:

Small sliding is assumed during substep. The nodal connectivity of the contact element is reformed

in the beginning of each substep and remains unchanged during iterations

- Bisection is performed if a large sliding distance is detected within a substep

- It can handle situations when contact pairs are initially in far-field and then come into contact

- The adaptive small-sliding logic often improves robustness/performance compared to the finite

sliding logic and can also improve solution accuracy compared to the small sliding logic

3. Detection Method

This selection allows the user to select a an algorithm for contact detection to aid in solution convergence. The following table is taken from ANSYS help. Note that the Nodal-Projected Normal From Contact is the latest and greatest method and is possibly the most robust. It often helps achieve convergence when other methods fail.

| Option | Description |

|---|---|

| Program Controlled | The application uses Gauss integration points (On Gauss Point) when the Formulation property is set to Pure Penalty or Augmented Lagrange. It uses nodal point (Nodal-Normal to Target) when the Formulation property is set to MPC or Normal Lagrange. When working with Gasket bodies, the application automatically selects the option, Nodal-Projected Normal From Contact. |

| On Gauss Point | The contact detection location is at the Gauss integration points. This option is not applicable to contacts with MPC or Normal Lagrange formulation. |

| Nodal – Normal From Contact | The contact detection location is on a nodal point where the contact normal is perpendicular to the contact surface. |

| Nodal – Normal To Target | The contact detection location is on a nodal point where the contact normal is perpendicular to the target surface. |

| Nodal – Projected Normal From Contact | The contact detection location is at contact nodal points in an overlapping region of the contact and target surfaces (projection-based method). Note: Additive Manufacturing Process simulations do not support projection-based contact. |

| Nodal – Dual Shape Function Projection | The contact detection location is at contact nodal points in an overlapping region of the Contact and Target surfaces (Dual Shape function projection-based method). This option is efficient in terms of solution performance and memory usage and generally remedies potential over constraint due to MPC equations. |

| Combined | The Mechanical APDL solver will use the optimized detection approach based on the bodies in contact. |

4. Penetration Tolerance

This setting allows you to input a value or factor for contact penetration. Read more about contact penetration.

5. Elastic Slip Tolerance

There is difference in sliding and slipping. Sliding refers to when there is relative translation of the components in contact. Slipping is the case when there is sliding as well as angular displacement.

The tangential interaction between contact surfaces is defined by two values – friction coefficient and elastic slip. Even if the friction coefficient is zero (frictionless contact) an elastic slip tolerance value will affect the slipping.

The use can set the maximum allowable slip as a value (length unit) or a factor (function of mesh).

| Option | Description |

| Program Controlled | This is the default setting. The Elastic Slip Tolerance Value is calculated by the application. |

| Value | Enter the Elastic Slip Tolerance Value directly. This entry is a length measurement (foot, meter, etc.). Only non-zero positive values are valid. |

| Factor | Enter the Elastic Slip Tolerance Factor directly. This entry must be equal to or greater than zero but must also be less than 1.0. This entry has no unit. |

6. Normal Stiffness

The normal stiffness value determines the behavior of the contact when penetration occurs. It provides a “restoring force” to enable penetrating nodes to stay within the defined penetration tolerance. The use can define a value of a factor for this.

7. Update Stiffness

The solver can automatically update the contact stiffness during the solution. This can aid greatly in achieving convergence. The following table is from ANSYS help:

| Property | Description |

| Program Controlled | This is the default setting. The application sets the property to Never for contacts between two rigid bodies and to Each Iteration for all other cases. You can change the default using the Options dialog. |

| Never | This is the default setting. Turns off the program’s automatic Update Stiffness feature. |

| Each Iteration | Sets the program to update stiffness at the end of each equilibrium iteration. This choice is recommended if you are unsure of a Normal Stiffness Factor to use in order to obtain good results. |

| Each Iteration, Aggressive | Sets the program to update stiffness at the end of each equilibrium iteration, but compared to the Each Iteration, this option allows for a more aggressive changing of the value range. |

| Each Iteration, Exponential | This option requires the Type property to be set to either Frictional or Frictionless and the Formulation property to Pure Penalty. When selected, the Pressure at Zero Penetration and the Initial Clearance properties display. This option updates stiffness using an exponential pressure-penetration relationship. For detailed information about this option, see the Exponential Pressure-Penetration Relationship (KEYOPT(6) = 3) topic (of the Set the Real Constants and Element KEYOPTS section) in the Mechanical APDL Contact Technology Guide. |

Check out FEA Tips eBook – All Models are Wrong

8. Pinball Region

ANSYS help provides a good explanation for this:

This option enables you to specify the contact search size, commonly referred to as the Pinball Region. Setting a pinball region can be useful in cases where initially, bodies are far enough away from one another that, by default, the program will not detect that they are in contact. You could then increase the pinball region as needed. Consider an example of a surface body that was generated by offsetting a face of a solid body, possibly leaving a large gap, depending on the thickness. Another example is a large deflection problem where a considerable pinball region is required due to possible large amounts of over penetration. In general though, if you want two regions to be bonded together that may be far apart, you should specify a pinball region that is large enough to ensure that contact indeed occurs.

For bonded and no separation contact types, you must be careful in specifying a large pinball region. For these types of contact, any regions found within the pinball region will be considered to be in contact. For other types of contact, this is not as critical because additional calculations are performed to determine if the two bodies are truly in contact. The pinball region defines the searching range where these calculations will occur. Further, a large gap can transmit fictitious moments across the boundary. Property options are described below.

| Property | Description |

| Program Controlled | This is the default setting. The pinball region will be calculated by the program. |

| Auto Detection Value | This option is only available for contacts generated automatically. The pinball region will be equal to the tolerance value used in generating the contacts. The value is displayed as read-only in the Auto Detection Value field. Auto Detection Value is the recommended option for cases where the automatic contact detection region is larger than a Program Controlled region. In such cases, some contact pairs that were detected automatically may not be considered in contact for a solution. |

| Radius | The radius value is input directly by the user. |

Geometric Modification

This topic is addressed in a dedicated article – ANSYS Geometric Modification Settings Explained.

Updates

Ansys regularly updates the contact settings and adds new features. Links to the updates will be provided here:

- Connections Manager

- 1D Folder

- Rigid to Flexible contact

- Cylindrical Smoothing