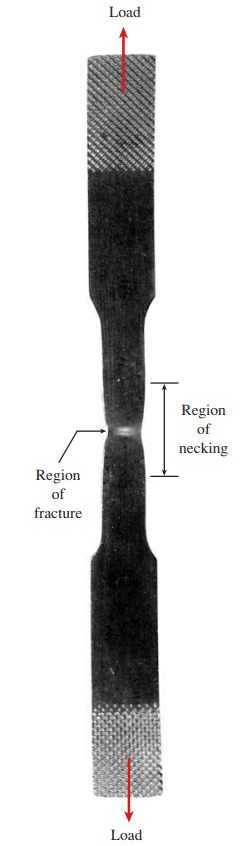

The axial stress in a test specimen is calculated by dividing the axial load P by the cross-sectional area A. When the initial area of the specimen is used in the calculation, the stress is called the nominal stress (other names are conventional stress and engineering stress). A more exact value of the axial stress, called the true stress, can be calculated by using the actual area of the bar at the cross section where failure occurs. Since the actual area in a tension test is always less than the initial area (as illustrated in Figure 1 by necking), the true stress is larger than the nominal stress [1].

This page is part of The Encyclopedia of Stresses in Solids